Across factory floors and bustling highways, a quiet revolution has transformed the way we approach automotive power. At its heart lies the turbocharged engine—an innovation that reshaped expectations about performance, efficiency, and what’s possible with a simple twist of a key. From racing circuits to rugged mountain crossings, turbochargers have empowered drivers to tap into remarkable reserves of power while meeting the growing calls for cleaner, leaner machines. In 2025, with brands like Garrett, BorgWarner, and Holset leading the charge alongside Toyota’s TRD and tech-driven designs from Mitsubishi Turbocharger and IHI Turbo, turbo tech isn’t just for adrenaline-seekers. It serves everyone from daily commuters to rugged trucking fleets, balancing raw force with smart engineering. As this article follows the journey of turbocharging—from its roots to its daily impact—a tapestry of innovation unfolds, all driven by a relentless quest for more.

How Turbocharged Engines Work: Principles and Operative Magic

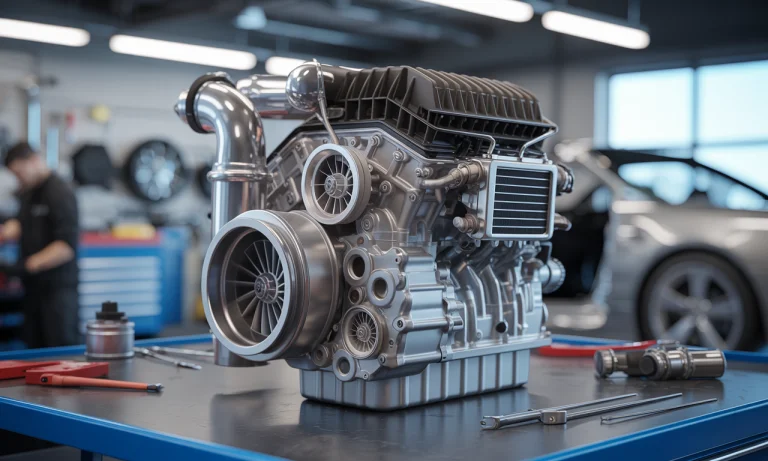

It started as a simple question for Luc, a young engineer at Precision Turbo: how do you squeeze more power from a smaller engine without guzzling fuel? The answer took him deep into the anatomy of turbocharging, where exhaust energy that once escaped uselessly is reimagined as a source of acceleration. In a modern turbo engine, hot exhaust gases spin a turbine—sometimes at speeds over 150,000 RPM—reclaiming energy that typically disappears down the tailpipe. This turbine, in turn, drives a compressor that forces dense, fresh air into the cylinders, amplifying combustion with every cycle.

This forced induction principle allows for efficient use of space and fuel, elevating a compact engine’s output to levels that rival much larger powerplants. Modern systems, often featuring innovations from BorgWarner or Cummins Turbo Technologies, incorporate variable geometry vanes or twin-scroll designs to cut lag and fine-tune responsiveness. The outcome isn’t just raw strength: it’s a highly adaptable, efficient propulsion system built from precise engineering and a careful balance of pressure and timing.

| Component | Function | Key Manufacturers |

|---|---|---|

| Turbine | Harnesses exhaust gas energy to spin the compressor | Garrett, Holset, BorgWarner |

| Compressor | Forces air into the engine to increase combustion power | Mitsubishi Turbocharger, IHI Turbo, Turbonetics |

| Intercooler | Cools compressed air to increase density and prevent engine knocking | Honeywell, Precision Turbo |

Understanding Energy Recovery and Volumetric Efficiency

At his workbench, Luc marvels at how each element contributes to a seamless operation. By recycling exhaust heat, turbocharged systems minimize waste, injecting each intake stroke with an abundance of oxygen. The effect? Superior volumetric efficiency—a term that, for Luc, means unlocking more torque and horsepower from every drop of fuel. Brands like Toyota’s TRD blend these technologies for enhanced performance, even at high altitudes or variable driving conditions, making turbocharging a pillar of 21st-century engine evolution. To learn more about how these improvements have shaped broader engine design, see this deep dive into engine evolution over the decades.

Main Components and Types of Automotive Turbocharging Systems

When Luc tours the local Honeywell research lab, he finds a puzzle of metal and precision: the heart of any turbocharged setup. Each wheel, casing, and sealing method tells a story of specialty and adaptation. The turbine—often developed by Garrett, Holset, or even Turbonetics for high-performance applications—extracts maximum force from spent exhaust gases. Connected by a high-speed shaft, the compressor takes over, packing more air into the engine for robust combustion.

Air that’s compressed also heats up, and without cooling, performance falters. That’s why intercoolers—sometimes engineered by Precision Turbo or BorgWarner—play a vital role. They reduce intake temperatures to ensure high-density, oxygen-rich air for the mixture, allowing the engine to avoid detonation and unlock safer, sustained bursts of power.

| Turbo Type | Benefits | Common Applications |

|---|---|---|

| Single Turbo | Simple, cost-effective, tunable for either response or top-end power | Compact cars, daily drivers |

| Twin Scroll | Reduced lag, increased efficiency, balance across RPMs | Performance models, modern sedans |

| Twin Turbo (Parallel/Sequential) | Broad powerband, minimized lag, top-end strength | Sports cars, high-performance luxury models |

| Variable Geometry Turbo (VGT) | Adaptive performance at varying speeds, minimal lag | Diesel, advanced gasoline engines |

Variable Geometry and Twin Scroll Turbos: The Evolution of Responsiveness

Manufacturing legends like IHI Turbo and Cummins Turbo Technologies have made variable geometry turbochargers (VGT) a new standard, particularly in diesel and high-performance sectors. These systems wield adjustable vanes inside the turbine, constantly optimizing airflow and pressure, seamlessly balancing low-end grunt with high-RPM firepower. Twin-scroll setups, as seen in recent offerings from Toyota (TRD), divide exhaust flow for sharper spooling—a testament to ongoing engineering ingenuity. This wave of innovation traces the trajectory of turbocharged engines from niche racing tech to everyday reliability. For a practical guide on keeping these systems at peak, see this piece on essential engine maintenance tips.

Benefits and Performance Advantages of Turbocharged Powerplants

On a rainy autumn morning, Anna, a taxi fleet manager, considers upgrading her vehicles to turbocharged Volkswagen Jettas. What tips the scale isn’t just acceleration but versatility—turbo engines deliver a deep well of torque, indispensable during city sprints and highway overtakes. The power output per liter, or specific output, far exceeds older, naturally aspirated designs. In practical terms, her drivers enjoy a smoother experience, less strain on long journeys, and, crucially, reduced fuel costs thanks to optimal combustion cycles.

Turbocharging technology is also adaptable: it performs consistently even at high altitudes, compensating for thinner air—a true asset on cross-country routes. The efficiency improvements mean lower CO2 emissions, helping the fleet meet stricter regulatory benchmarks. Anna’s experience echoes a broader industry shift, as manufacturers like Garrett and BorgWarner expand turbo implementation into hybrid and downsized engines, keeping the industry future-proof. Insights into optimal oil selection for these high-output engines are explored in this resource: Choosing the Right Car Engine Oil.

| Advantage | Impact |

|---|---|

| Increased Power | Small engines deliver outputs matching larger peers |

| Fuel Efficiency | Extracts more energy per unit of fuel |

| Altitude Performance | Maintains power in thin air environments |

| Lower Emissions | Drives smaller, cleaner engines without performance loss |

| Downsizing | Lighter, more efficient vehicle options |

Everyday Thrills: Real-World Advantages of Turbo Cars

For casual drivers and enthusiasts alike, the turbo difference is tangible. Whether it’s the immediate thrust when overtaking a truck or the persistent efficiency during family road trips, the experience makes turbo cars stand out. Modern turbocharged engines—whether fitted by Toyota (TRD), Holset, or Turbonetics—combine advanced fueling, cooling, and durable construction to ensure longevity. Still, as oil quality is critical for these highly stressed systems, Anna insists on regular checks after reading up on how oil type affects turbo engine performance.

Navigating Challenges: Turbo Lag, Heat, and Maintenance

Not every day is seamless for Luc or Anna. The specter of turbo lag—delayed response between throttle input and actual boost—still tests drivers’ patience, especially in older or poorly maintained models. Companies like Honeywell and Mitsubishi Turbocharger counteract this with electric assist and novel valve mechanisms. Yet, high operating temperatures remain a hurdle, demanding sophisticated intercoolers and premium lubricants.

Maintaining consistent oil flow is non-negotiable. A lapse can lead to rapid degradation of turbo bearings, a lesson many performance enthusiasts have learned the hard way. Regular, quality maintenance—paired with intelligent boost control systems and resilient engine internals—is critical for longevity. As turbocharging grows more common, professional service networks and new diagnostic tools make proper upkeep more accessible than ever before, both for seasoned tuners and first-time turbo owners. For a primer on balancing complexity and reliability, this resource on modern engine care is invaluable.

| Challenge | Solution Strategies |

|---|---|

| Turbo Lag | Twin-scroll turbos, electric assists, variable geometry |

| Heat Management | Efficient intercoolers, advanced materials |

| Oil Quality | Synthetic/engineered oils, regular maintenance |

| Component Wear | Robust design, careful stress testing |

Spotlight: Top Turbocharged Cars and Industry Leaders in 2025

In the showroom’s gleam, Anna’s fleet options abound, each model showcasing a unique blend of tradition and turbo innovation. The Subaru WRX STI, Golf GTI, and Honda Civic Type R headline a field where turbo tech marries rally heritage with everyday pragmatism. Legendary builds like the Nissan GT-R and Porsche 930 sit alongside practical wonders like the KIA Forte 1.6 or Volkswagen Jetta—demonstrating turbocharging’s reach, from track to town. Industry titans—Garrett, Precision Turbo, TRD, BorgWarner—supply the muscle behind these machines, each pushing the limits further.

The boom in turbo popularity isn’t without reason. Beyond power, drivers appreciate high-altitude performance, better towing, and that unmistakable burst of acceleration. These traits underscore why turbocharged cars dominate conversations among both first buyers and veteran enthusiasts. The future, shaped by continued R&D at Mitsubishi Turbocharger, Turbonetics, and IHI Turbo, promises even more accessibility and refinement as emissions targets tighten worldwide. For a full guide comparing classic and new turbo favorites, browse this analysis at Engine Technology Evolution.

| Model | Turbo Supplier | Distinguishing Features |

|---|---|---|

| Subaru WRX STI | Mitsubishi Turbocharger | Rally pedigree, AWD, sharp response |

| Honda Civic Type R | Honeywell | Track-tuned, aggressive torque |

| Golf GTI | Garrett | Iconic “hot hatch” balance |

| Nissan GT-R | IHI Turbo | AWD, legendary acceleration |

| KIA Forte 1.6 | BorgWarner | Everyday utility meets sporty thrust |

Selecting the Right Turbo Car: Insights from Industry Experience

Choosing the ideal turbo automobile blends technical checks with lifestyle preferences. Anna opts for models with advanced smart navigation and robust warranties, while Luc, ever the tinkerer, prioritizes brands with accessible aftermarket support (Turbonetics or Precision Turbo being favorites). Reading user feedback and examining real-world mileage figures matter as much as any test drive, especially as today’s turbo engines continue evolving. For detailed advice on maintenance and longevity, this specialist overview on car engine upkeep is a solid reference point for both new and seasoned owners.

Frequently Asked Questions about Turbocharged Engines

Are modern turbocharged engines more fuel efficient than naturally aspirated engines?

Generally, yes. A smaller turbocharged engine can generate the same or more power than a larger naturally aspirated engine, often with improved fuel efficiency—especially when driven moderately. However, spirited driving can still impact consumption.

Which manufacturers are most trusted for turbo components in 2025?

Garrett, BorgWarner, Holset, Mitsubishi Turbocharger, IHI Turbo, Precision Turbo, Cummins Turbo Technologies, Honeywell, Toyota (TRD), and Turbonetics are recognized leaders, each catering to different performance, reliability, and design niches.

What’s the main drawback of turbocharged vehicles for everyday use?

The primary concerns are potential turbo lag, greater complexity—which can increase maintenance costs—and the need for premium oils and strict servicing schedules. Yet, advances in system design are steadily reducing these issues.

Is it possible to retrofit a turbocharger onto a car that wasn’t originally designed for one?

Yes, but it requires significant mechanical modifications, expert calibration, and can impact long-term reliability if not done correctly. Direct consultation with specialists and comprehensive upgrades are crucial.

How can owners maximize the lifespan of their turbocharged engines?

Regular oil changes using high-quality lubricants, routine intercooler cleaning, and gentle warm-up before spirited driving are vital. For tailored tips, review this practical maintenance guide.

Did you like it? 4.5/5 (27)